The Argentine double layer roofing sheet machine is a high-performance forming equipment that can produce two different types of tiles. It is suitable for customers with limited space. The tile type can be customized according to customer needs.

The double-layer roofing sheet machine is equipped with a clutch device, ensuring that the upper and lower layers of tiles on the machine do not operate simultaneously. This reduces the wear on the roller and extends the machine’s service life.

(clutch device)

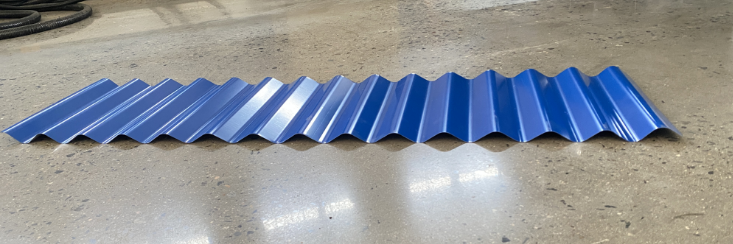

Below is the finished product:

Main parameters of Double Layer Roofing Sheet Machine For Argentina

Machine frame: 350mm H beam structure, with 18mm welded steel middle support plate.

Material of rollers:

High grade 45# forged steel Chromed treatment (Chrome thickness:0.05 mm)

make the rollers surface more smoothly, improve the hardness and prevent abrasion, anti corrosion increase of service life

Forming stations: Upper layer18rows

Lower layer20 rows

Rolling type: separate rolling design concept, it can release nternal stress from the sheets, then the sheet will be in good shape and high precision.

Diameter of shafts: 80mm solid

Material of shafts: High grade 45#,with heat treatment

Forming speed: 0-15m/min

Voltage: 380V/50HZ/3P (as requested)

Transmission way: By 1 inch chain (double chains)

Main motor: 7.5 KW

Cutting blade material : Gcr12 quenched treatment

Cutting type: hydraulic post cutting

Driving method: By pillar type Cylinder

The handwheels on both sides can be used to adjust the feeding width, and the four stainless steel rollers allow the material to enter the machine smoothly, preventing the material’s surface from being scratched.

Main roll forming system of double machine producing two types of ibr roof sheet

1. The frame is welded with H-shaped steel, and the design of inclined support rods and strengthening beams enhances the strength of the frame. The lifting ears, lifting holes, and lifting holes are designed for loading and unloading.

2.Our rollers are typically made from raw materials that have undergone hard chrome electroplating treatment, resulting in high durability and a long lifespan. This process also prevents rust and keeps the product clean.

3.The size of the shaft is 80 mm, and according to your needs, the material reinforces our shaft for durability and is not easy to damage.

4.The shaft and roller are connected by a keyway to prevent the linear speed of the shaft from being inconsistent with the roller, thereby avoiding vibration.

5. The design of the positive and negative adjustment bolts, double locking bolts and stop washers prevents the shaft from loosening when the machine is running, and the partition is made of seamless steel pipe, which is not only sufficiently reinforced, but also not easy to rust after being boiled black, ensuring normal operation.

Our machine uses 8.8-grade bolts, along with flat washers and spring washers. Solve the problem of loose bolts caused by vibration during the transportation, production, and operation of the equipment. For your reference.

Hydraulic Shearing

The blade material is Cr12, the upper blade is inserted into the frame, and each blade is fixed with two rows of bolts and nuts, with high stability.