The Floor Decking Roll Forming Machine is an advanced industrial wonder in form forming. This cutting-edge equipment is designed to produce high-quality metal roof panels efficiently. Floor Decking Roll Forming Machine adopts advanced roller forming technology, which can easily shape the metal plates into precise and uniform roof panel contours. Its automated operation ensures consistency and accuracy, thereby optimizing production efficiency and reducing labor costs. This machine has a wide range of applications and can produce metal roof panels of various sizes and designs to meet different construction needs and engineering specifications. Its complex engineering design and advanced control system make it an indispensable tool for manufacturers, aiming to provide reliable and durable metal roofing panels for commercial, industrial, and residential buildings.

What is the metal roofing decking ?

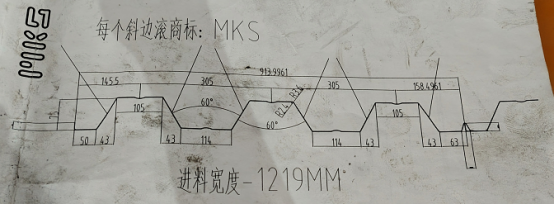

Floor Decking panels come in various types, including narrow ribs, medium ribs, wide ribs, and deep ribs, which are used to support the insulation layer of the roof or lightweight concrete as well as waterproof membranes. Our metal roof panels, due to their high strength-to-weight ratio, can be used as the foundation for flat steel roof panels, pitched steel roof panels, and arched roof panel systems. Metal roofing panel products can independently transfer horizontal and vertical loads to the building frame. It is suitable for open ceiling designs or designs with additional sound-absorbing holes. In addition, metal roofing panels are also renowned for providing a solid working surface and can be used to install insulation layers, weatherproof materials, and roofing materials.

The drawing profile for your reference:

Floor Decking Roll Forming Machine finished products:

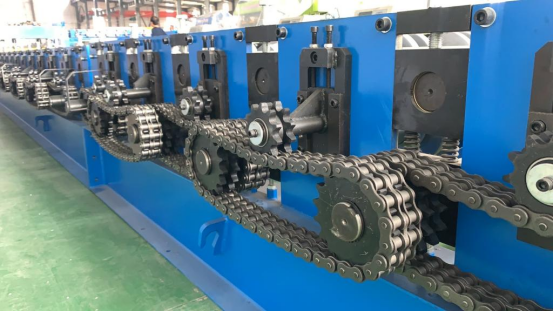

Floor Decking Roll Forming Machine:

Advantage of Floor Decking Roll Forming Machine:

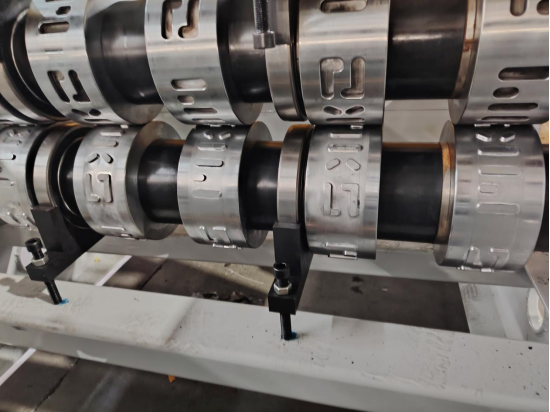

Using the 95mm solid shaft and H-shaped steel as the base frame, the machine can withstand long-term production without deformation, thus ensuring the long-term service life of the machine; for the metal embossing roller, we use a strong shaft with a diameter of 120mm, and adopt a tone design at the same time.

2. The roller is processed by CNC machine tools to ensure the accuracy of the roller, thus ensuring the accuracy of the final deck. For the metal embossing roller, we designed a brake system that can easily feed the coil to ensure the beauty and precision of the embossing.

3. Our cutting blade frame is stress-relieved to ensure that it does not deform in long-term production, making the final product smooth. The shear frame system has a long service life.

4. The steel deck is flat, the accuracy is within 1mm, and the effective width is controlled within 5mm; when shearing, there will be some waste rolls.

5. It adopts Delta or Siemens operating systems, featuring stable performance and simple operation. Just input the length and quantity, and the machine will automatically produce. The cutting length tolerance is within ±2mm.

6.The forming speed can reach 8 to 12 meters per minute.

7.The machine weighs approximately 15 to 18 tons.

8. Our equipment uses a double-edged knife. The two blades at the bottom are the same as the version, and there are many saws on the top to ensure that the cutting is not deformed, but there will be a small amount of waste.

9.There is a gear device on the side, with tensioned left and right, to prevent the chain from loosening due to long-term use