Metal tiles are widely used all over the world. First of all, it is waterproof and leakproof, making the house look more beautiful, soundproof noise-reducing, and heat-insulating.

The High speed high quality roof tile roll forming machine adopts gearbox transmission and is a higher-configuration roll-forming machine. Although the speed is not very fast, the speed of 25 meters/minute can already meet the production needs of most factories. In fact, this roll-forming machine pays more attention to safety and stability. While producing a perfect sheet profile, the quality of the machine is also crucial. We provide good after-sales service, including free replacement of non-artificially damaged parts, and free and timely technical support throughout the service life of the machine.

The high speed high quality roof tile roll forming machine driven by the gearbox has the following characteristics and advantages:

1. High production efficiency: Due to the gearbox transmission mode, it can achieve high-speed operation, quickly produce tiles, and meet the needs of large-scale production.

2. High precision: The high precision of gear transmission makes the size and shape of tiles more regular and uniform, ensuring the stability of product quality.

3. Good stability: The gearbox structure is relatively stable, and the performance is stable during high-speed operation, ensuring trouble-free operation.

4. Strong durability: The gearbox transmission components are carefully designed and manufactured, with a long service life, and maintain good working conditions during long-term production.

5. Improve production efficiency: High-speed production capacity shortens the production cycle of tiles, can be quickly supplied to the market, and brings higher benefits.

The working flow : Uncoiling → Feeding material into machine → roll forming → Products receiving table

Video:https://youtu.be/6UPFXrxHjcE?si=ebWPgK-WDQUCBPDp

Thickness : 0.3- 0.8mm

high speed high quality roof tile roll forming machine

Automatic decoiler: Capacity can customized according to customer needs 5T/10T/15T

It has press arm to keep the coil from loosing

It has speed sensor to match with the whole line’s speed

high speed high quality roof tile roll forming machine

The feeding part: Steel plate welded as the feeding platform

One set guiding roller

Main parts of the machine: Rolling stations: 23 rolling stations

Machine base frame: cast iron arch frame: strong and durable, high precision

Working speed: 0-25 m/min

Rolling shaft: shaft material: 45# steel

Shaft type: solid shaft

Shaft diameter: 80 mm, tempered to prevent deformation and increase hardness

Transmission: gearbox transmission, faster speed, and higher precision

Hydraulic cutting system

Driving method: By pillar-type Cylinder

Hydraulic motor power: 5.5 kW

Cutter material: GB-Cr12

Cutting feature: Steady and safe working conditions

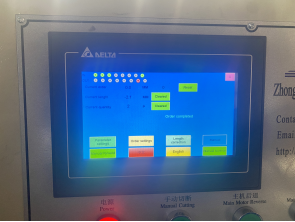

PLC control system: Siemens

PLC brand: Siemens

Screen type: Touch screen, also have buttons on the panel

Siemens remote control system

Automatic stacker: the length of the machine can be customized