As the name implies, the R panel roofing sheet machine series is mainly used to manufacture R panels which are one of the most commonly used metal siding and roofing panels in commercial steel structure buildings. Changzhou Zhongtuo International Trade Co., Ltd. conducts strict quality control throughout the manufacturing process and provides high-quality, different specifications of R Panel Roofing Sheet Machines at favorable prices. For more information about the siding machine, please feel free to contact us.

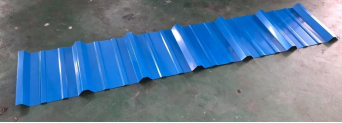

Here is one drawing profile and finished product:

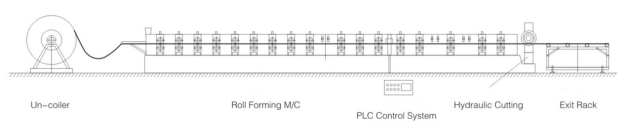

Processing Flow

Uncoiling → Feeding material into machine →Roll forming → Auto cutting →Products receiving table

R panel roofing sheet machine

R panel roofing sheet machine

Our machine frame is welded with steel plates, and the machine wall thickness is 20mm, which is very strong. The number of forming rollers is 20 rows, but it can also be customized according to customer requirements, and the extruded version is accurate and beautiful.

The control system adopts the world-renowned Siemens brand, which can provide remote control and simple and convenient operation. We are responsible for the quality of the machine, and we are also responsible for after-sales service. We can provide manuals, engineer remote teaching, and engineer on-site service.

The rollers are chrome-plated to prevent wear, have a solid shaft connection, and double chain drive, sturdy and durable. The machine runs at a speed of about 15 meters/minute. It adopts a hydraulic cutting system, a hydraulic station with an air cooling device, a Cr12 tool, and no burrs.

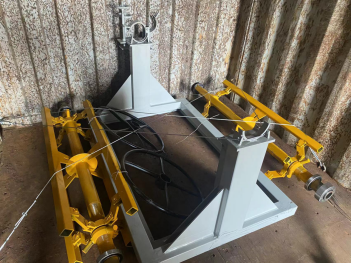

5T Manual Decolier For Free

Capacity:5 tons

Coil inner diameter:450-550mm Feeding width: max 1220mm Structure: welded by the steel plates and profiled bar.

The core contraction and expansion are manual, equipped with a manual brake, and the coil is pulled by the plate rolling machine for forward and reverse rotation.

Feeding Device

Hand wheels on both sides can be used to adjust the feeding width.

Four stainless rollers can make the material go into the machine smoothly and prevent the scratch on the material surface.

Roll Forming And Transmission Device

1.rollers thick chromed good hardness for long service time.

2.Each roller has number and with keynotes, it can fix on the shaft stablely

3.gear and double chain,stable

Hydraulic Cutting Device

We use four pillars cutting system structure, it can make sure the cutting stable

PLC control system

PLC brand: Delta (Taiwan) PLC, inverter and touch screen

● Encoder brand: Omron

● Electrical components: Schneider

● Operating language: English and Chinese (or as required) You can set up orders in this section, change product length and quantity, the operation is very simple, and it is equipped with aviation plugs, which is convenient for installation when the machine arrives.

Hydraulic station

● Hydraulic station motor: 5.5 KW

● Hydraulic oil:46# hydraulic oil

● Main components:Include a set of hydraulic tank, a set of hydraulic oil pump, two hydraulic pipes. And one of electromagnetism valve